APESS®

Things are sometimes a lot simpler than you think.

This also applies to some extent to APESS® technology. It’s not a new invention, or even a finished product. APESS® systems use many more patented processes for the optimised use of tried and tested components in ventilation and air conditioning technology that have proven their worth a thousand times over on the market.

ECO

The idea

Apess®

Patents

- Method and device for energy recovery

- Device for heat recovery in a heat exchanger system

- Device for increasing heat output and energy buffering in a heat pump

- Device for heat recovery from wastewater

- Device for re-cooling heat carriers and working materials from refrigeration technology and liquid coolers as well as cold recovery in ventilation technology

Apess®

Components

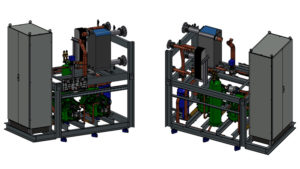

APESS® Energy Management Unit – „EMU”

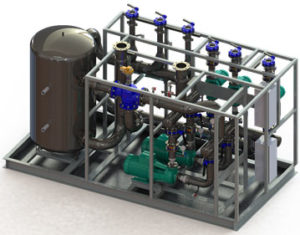

The EMU is a compact and uniquely optimised circuit connect system with the patented Q-Optimum process for maximum energy recovery. Its patented process excludes measurement tolerances for density and humidity in the air as well as air volume flows, and therefore has impressive, unrivalled accuracy. EMU also takes into account the calculation with condensation in the exhaust air and frost protection at low outside temperatures—another unique APESS® feature!APESS® hydraulic modules

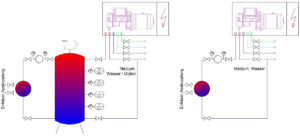

With APESS® cold and heat transfer modules, the Coefficient of Performance (COP) of the heat pump (see also EER (energy efficiency ratio) and ERP (enterprise resource planning)) is achieved through optimal hydraulics control. These modules are part of the process patent for energy recovery (process and device for energy recovery). The hydraulic module with integrated buffer is also part of the patent and ensures optimal use, minimum operating and idle time of the heat pump. Overall, this minimises heat pump operating costs, extends their service life and reduces CO2 emissions. In order to make this possible, the heat carrier flow temperature is only set to the necessary energy output and the excess energy is temporarily stored in the buffer tank. . If desired, a boiler, solar thermal, biogas, waste heat recovery or other energy generators can be integrated into the hydraulic system. The technology is also extremely flexible: it can be set up as a local system or as a central, integrated system.APESS® heat pump

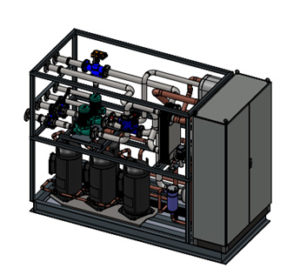

APESS® heat pumps are the only ones on the market equipped with a device for controlling heat pump heating power with thermal energy buffering. This overall control (including the refrigeration process) vastly increases efficiency. Thanks to this sensitive control, natural refrigerants such as carbon dioxide (CO2), propane or ammonia can be used. This is a huge plus for environmental protection. Since the “global warming potential” of natural refrigerants is almost zero, they are cheap and readily available.APESS® desuperheater

With APESS® technology, the temperature of the heat pump after the condenser (heat exchanger) can be brought to a higher temperature, as the medium in the desuperheater is and remains gaseous. This means that cooling can start from a higher temperature level.

Hot gas cooling of the refrigerant takes place in the desuperheater, which achieves an optimal COP (COP = 4, at a hot water temperature of 65°C).

In cold weather, for example, hot water can be provided free of charge during the summer months.

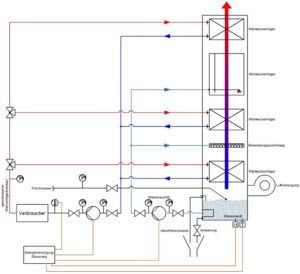

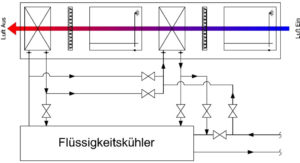

APESS® recoolers

APESS® recoolers use their own efficiency process to reduce the air volume flow when recooling heat carriers and working materials in the refrigeration technology. At least one air duct, one heat exchanger and one upstream humidifier are required. The humidifier creates an aerosol in the air flow before it reaches the downstream heat exchanger.

A great advantage – the reduction in the air volume flow rate means that y smaller dry coolers can be used because less cooling capacity is required.

Overall, the efficiency (EER) improves, the acquisition costs are lower and, in Austria, exhaust air humidifiers are 100%-subsidised.

Another highlight is that this APESS® technology enables the perfect combination of CO2 heat pumps with ventilation units because it can ensure that the return temperature to the heat pump is always below 29 °C.

The recooler is patented as a “device for recooling heat carriers and working materials from refrigeration technology and liquid coolers as well as cold recovery in ventilation technology”.

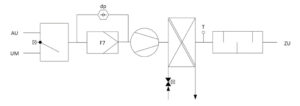

APESS® Satellit

Alternative space heating system

The Satellit makes it possible to ventilate, heat and cool individual rooms or entire buildings without any special intervention in the wall architecture. This system is highly suitable for old buildings and is therefore perfect for schools, nurseries and other public buildings. The APESS® Satellit makes it possible to create an efficient and environmentally friendly room climate using heat pumps without major conversion work.

Functions:

- supply air heating

- supply air cooling (non-condensing)

- convection heating

- forced air cooling (non-condensing)